Arai Hand Made

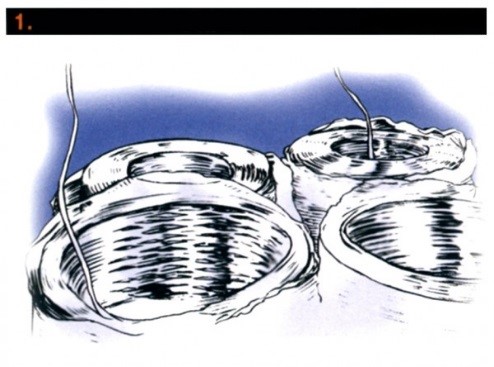

1. The construction of the outer shell is the start of the helmet manufacturing process. Super-Fiber strings form the base of the shell. Besides Super-Fiber, other materials such as Kevlar®, Nylon and carbon fiber are used on selected shells. |

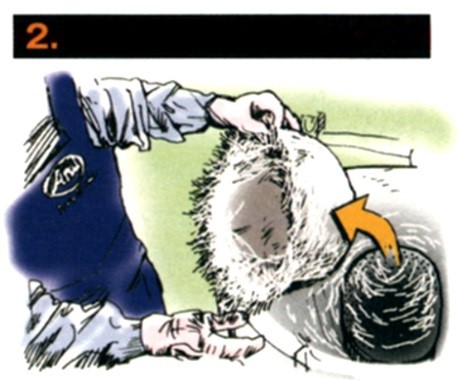

2. Super-Fiber strings are chopped and then sprayed on a metal mesh mold in a chamber,and shaped into what looks like a straw hat. |

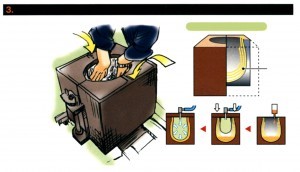

3. This “straw hat” together with additional Super-Fiber and other fiber materials are put in a molding device, and then resin is poured into the mold. The molding device is then closed tightly with a lid that has a balloon underneath it. The balloon is inflated and the molding device is heated to form an outer shell.A) Molding device and helmet molding B) Layers of fiberglass C) Pouring resin in D) Closed molding device lid, with balloon underneath E) Inflating the balloon

|

3. This “straw hat” together with additional Super-Fiber and other fiber materials are put in a molding device, and then resin is poured into the mold. The molding device is then closed tightly with a lid that has a balloon underneath it. The balloon is inflated and the molding device is heated to form an outer shell. A) Molding device and helmet molding B) Layers of fiberglass C) Pouring resin in D) Closed molding device lid, with balloon underneath E) Inflating the balloon

|

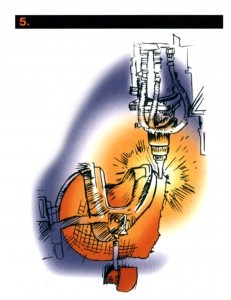

5. The visor opening, chin vent and other vent holes are cut out by a laser-cutting robot. |

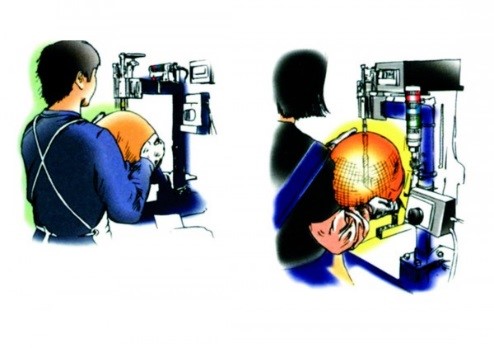

6. Every shell is then carefully inspected for thickness, weight and structural correctness. Then it is sent to another inspection department for final inspection. Each outer shell is therefore inspected twice. |

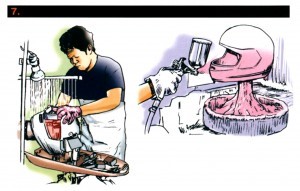

7. Passed shells are then undercoated and sanded. This process is repeated twice, to get a fine, even surface for a smooth finishing coat. | 8. Decals are applied onto the shells for models that come with graphics. |

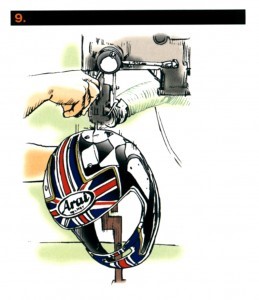

9. Holes for visor, chinstrap and ventilation ducts are drilled, and then the shells are trimmed with edge rubbers. | 10. The shock absorbing inner shell Is installed into the outer shell. |

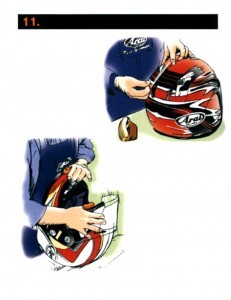

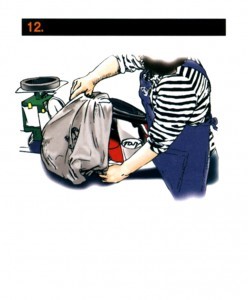

11. Visor, ventilation ducts and other parts are mounted, making sure each part fits and functions properly. | 12. After polishing and labelling each helmet is inspected carefully, and then proceeds to packaging. |

|

|