Arai Helmet Anatomy

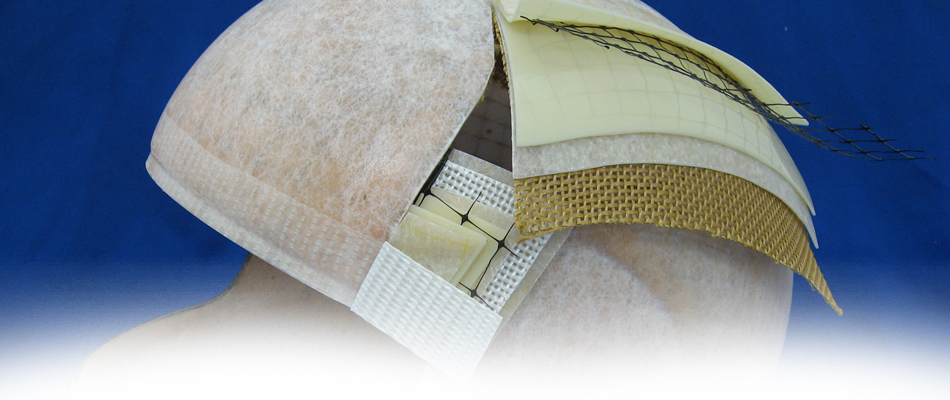

Basically a helmet consists of:

1) The outer shell

2) The inner shell

3) Comfort material

4) The retention systemIn addition, the following can also be part of a helmet:

5) Holders

COMFORT MATERIAL

The comfort material is made of urethane foam, covered with (cloth) nylon webbing. On selected models Dry-Cool® liner material is used, that dries extremely fast and disperses transpiration and heat much faster than conventional liners. In combination with the inner shell, the inner liner provides a snug and comfortable fit, which is of course important for the performance. The luxurious absorbent liner breathes and disperses moisture. The entire interior is washable in place, just clean with mild soap and lukewarm water, rinse well and let it dry for a day, never in direct sunlight or near a stove. Several Arai models feature complete or partly removable interiors. These may also be cleaned and washed, just place them in the washing machine. Different size thicknesses are available to fit those in-between sizes for a custom fit for every rider.

THE FASTENING DEVICE

In case of an accident, you may be subjected to impacts that occur coming from any direction. Some may tend to lift the helmet from your head. The function of the fastening device is to hold the helmet on the head in case of an accident. Therefore it is absolutely necessary that the chinstrap is securely fastened, keeping your helmet firmly in place whenever you ride. The famous Arai patented ‘Double-D’ ring buckle is well known and, although conventional, generally accepted as the best and most efficient fastening device within the helmet industry for a long time. It is the mandatory fastening device in many racing disciplines including MotoGP. The flat and D-shaped rings fit smooth against the chin, no moving parts, no corrosion problems and just pulling the tab is enough to loosen the fastener. One-touch quick-release fastening devices are common on the market, but may malfunction if dust, sweat, oil or corrosion affects such a fastening device.

The user might think that the chinstrap is fastened securely while actually the fastening device may not be secured properly. Another disadvantage of the quick-release fastener is that it might press uncomfortably against the wearer’s jaw when the chinstrap is secured tight. Therefore Arai has designed a flat D-ring that is smooth to the wearers jaw, eliminating pressure caused by ordinary fasteners, providing absolute secure fastening. Another advantage of the D-ring fastener is the fact that everybody understands how it functions and can therefore easily be released in case of an emergency. Arai’s cloth covered chinstrap is made of tight woven nylon ‘’66’’ webbing that is chaffing and splitting resistant and mounted to the outer shell by means of stainless steel rivets. The chinstrap has a small red push button to attach the strap end, which can only be fastened if the chinstrap has been tightened in the proper way. If the button is closed without looping through both “D-rings”, it can easily be noticed, because the chinstrap will feel sloppy as a warning. A red release tap allows easy loosening of the chinstrap even when wearing gloves. Both approval label and production date of your Arai helmet can be found on the fastening device. The ECE 22-05 orange approval label is sewed on the chinstrap. The production date can be found impressed on the left chinstrap or laser etched on the steel D-ring fastener. This date is offered as a code with the production month followed by the year. For instance 04/11 stands for production date April 2011.

HOLDERS

A holder plate covers the Arai visor mechanism. This is done with a purpose. Holder less visor systems are easier to make: a simple deep, flat recess in the shell surface to hold the visor pivot mechanism. But Arai’s experience tells us these deeply recessed pockets (some as deep as 12 mm) aren’t a good idea because either the interior liner must be made thinner and harder in the recessed area, or the shell must be made larger to accommodate a thicker, softer liner.

But more important, the deep recesses can have sharp edges that may impede the desired smooth dispersal of impact energy along the shell’s naturally curved surface. Arai’s holder system lets us maintain a shallow recess (as much of the pivot mechanism is within the shield itself) with round edges, so energy can flow more smoothly over the entire shell shape. The holder system isn’t easy to design, or cheap to build: the shell surface beneath the pod continues the three-dimensional shape of the shell with a series of difficult compound curves that the holders base plate mechanism must conform to.